Wednesday, May 26, 2010

kontraktor

haha....

ambo ni tak sampai tahap kontraktor...juz kuli sahaja...

ambo hanya pekerja biasa....daripada bidang aerospace....berjinak2 bidang civil...

bekerja dengan bapa saudara....membuat rumah size sederhana....memang memenatkan...bermula dari membuat tapak.....sehinggalah konkrit, seterusnya mengikat jongkong untuk dinding.....

dan seterusnya...sudah 2 minggu ambo bekerja...selepas abis final exam...balik kg...terus cari kerja....

kerja ni memang sangat penat....fullly use your body strength....contohnya gaul simen untuk konkrit....satu beg simen ( 50 kg ) + 5 kereta sorong batu pasir....then dalam mase satu hari gaul sampai 12 beg simen.....so...pasir tambah simen dalam 60 kereta sorong gaul simen + batu pasir + air....ni baru dalam masa 1 hari.....fuh!!!

lupe nak kira brape kg sume...tangan ni ase macam ringan je bila balik rumah....haha...

memang jd tough...kulit pun habis hangus duk tengah panas....

dah 3 kali col dari spirit aero systems....offer praktikal...kawan2 sume x nak pergi..lau yg nak pergi, mak ayah x bagi...huhu...dorang nak continue degree terus sume...

camne ni??

Sunday, May 9, 2010

maaf kerana melukakan hatimu

sometimes....my hearts not fully belongs with you....

i was bound to find out that you didn’t care

simpan sisa-sisa cerita cinta berdua

walau tak tercipta cerita cinta berdua

memang salah diriku yang tak pernah memahami mu...

maafkan daku...

menyisihkan dirimu....

segalanya sudah terlewat....

kini....ku sudah tidak penting lagi....

kau sudah tak perlukan lagi insan hina seperti ku....

selamat tinggal segalanya....

pesananmu amat berharga....

jangan abaikan orang yang betul2 sayangkan awak....

jangan sisihkan mereka....

i’m sorry i was a point you were destined to miss

Friday, May 7, 2010

mak.....

anak mak ni....

kadang2 malas mak....

study pun....bile ase nk study....

mak.....

mak slalu pesan mcm2...

tapi anak mak ni....

kadang2....lupakan pesanan mak.....

mak...

slalu mak bagitau...

mak....

anak mak ni ade suke kat seseorang...

tp x bagitau pun kat mak....

mak....

skang bukan mase yg sesuai untuk bercintan cintun kan....

skrang masa untuk belajar...

mak.....

anak mak ni.....

nangis dulu....nanti da ok sambung balik...

Di jiwa insan yang mendambakan kebahagiaan

Oh? ibu

Di bahumu tergalas beban

Perjalananmu penuh rintangan

Kau titipkan kasih sayang

Sejujur pengorbanan

Tak ku nafikan

Di saat kita berjauhan

Rasa ingin ku berlari

Mendakapimu penuh girang

Bak si kecil kehilangan

Kau insan penyayang

Betapa ku merindu

Lembutnya belaian ibu

Membuatku terlena

Di wajah terlukis tenang

Debar di dada kau rahsiakan

Ku pastikan dikau aman

Dikurnia sejahtera

Tak ku lupakan

Di saat kita berjauhan

Rasa ingin ku berlari

Mendakapimu penuh girang

Bak si kecil kehilangan

Tiada aku tanpa ibu

Hanya (kau) satu didunia

Bertakhta dikau dijiwaku

Kau lah ibu yang tercinta

Kau insan pengasih

Betapa aku mengharap

Hadirnya restumu ibu

Membawaku ke syurga

Bersemi belaian kasih sayang nan berpanjangan

Darimu insan yang mendoakan kebahagiaan anak-anakmu

Oh? Ibu

Lagu : Manis Helma (Hijjaz Records)

Lirik : Alif Lam Ra (Gurindam Entertainment)

Susunan Muzik : Along Exist, Isman Isam

Penerbit : Zahid, Isman Isam

Hakcipta : Hijjaz Records

Thursday, May 6, 2010

SPIRIT AEROSYSTEM

ni company yang buat body untuk airbus dan jugak boeing....bukan sume part la....certain part mcm wing....fuselage....spoiler...elevator...nose...fairing...flap...dan banyak lagi...

practical training offer !!!!

ni la mr kenney....hehe...x paham pe die speaking....pekat sgt

sampai2 terus dapat makan....hehe

ade offer ni dari spirit untuk praktikal selama 6 bulan....nak pergi ke tak nak yea??

huhu....

elaun rm 500 shj sebulan..

Headquarters:

Spirit AeroSystems

3801 S Oliver St

Wichita, KS 67210

| Company Name : |

| Spirit AeroSystems Malaysia Sdn Bhd |

| Industry : |

| Aerospace / Aviation / Airline |

| Type of Company : |

| Private Limited Company |

| Location : |

| Pusat Aeroangkasa Antarabangsa Malaysia (MIAC), LTSAAS, Subang, 40150 |

Monday, May 3, 2010

EYELASH

Reality, infinity

All the pieces here

Athletic shoes, Chocolate mousse

Cellular phone in his room

You will see one day, I'm here to stay

Hold your hand to me

We'll find a way

Lightning streaks, teary bliss

Slicking on the grease

With company you will see

What this all is meant to be

You will see one day, I'm here to stay

Hold your hand to me

We'll find a way

Close your eyes, snip your lashes

They fall within the ashes

The frosty old feeling, will melt oh so painlessly

Close your eyes, kill the darkness

The shears are in the closet

The muses they pray loud

For your listless journey to me

Innocence, garlands burn

All the memories

Transparencies, you will see

What this is meant to be

You will see one day

I'm here to stay, hold your hand to me

We'll find a way

Close your eyes, snip your lashes

They fall within the ashes

The frosty old feeling, will melt oh so painlessly

Close your eyes, kill the darkness

The shears are in the closet

The muses they pray loud

For your listless journey to me

Reality, infinity

All the pieces here

Athletic shoes, chocolate mousse

Cellular phone in his room

thanx ainan

Sunday, May 2, 2010

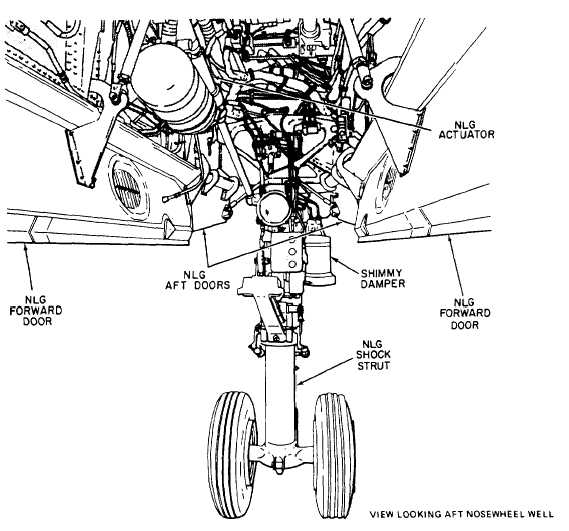

Steering Systems

Some a/c have free castering nose wheels; most have steerable.

Mechanical Steering Systems

Uses foot power to steer the aircraft – no assistance

Some types will disengage when the gear is retracted

Some types have an automatic centering device when weight is off the a/c

Tail Wheel

Conventional gear use the tail wheel to steer

May be a castering type with no steering capabilities (rudder steers)

May be lockable, for parking purposes

Power Steering Systems

Used where large amounts of force are required to steer

Controlled by pilots rudder pedals, OR

By a steering wheel, OR

By a combination of both

Most will require a towing bypass valve which allows

Ground crews to to the a/c without damaging the system

Retraction Systems

Purpose: reduce drag, or adapt a/c for landing on different surfaces

(consider retractable wheels on float systems)

Mechanical Systems

Crank mechanism, or uses a lever pulled by the pilot

This method may use a mechanical latch system to lock wheels “up”

No emergency backup available for this system

Electrical Retraction Systems

Uses a central motor and push-pull rods

Uses microswitches to detect when gear is down/locked, or up/locked

Hydraulic Retraction Systems

Most common system of retraction for most sizes of a/c

Used exclusively where landing gear is too large to be retracted by other methods

May use ED pumps, electric pumps, hand or wind-driven pumps

Emergency Landing Gear Systems

4 possible methods of dropping gear when hydraulics are lost:

air bottle “blows” the gear down

hand crank or ratched

separate hydraulic system (may be hand pump)

mechanical system which releases UP locks, and gear free-falls

Landing Gear Operation

4 main components:

shock strut

the wheel

the brake assembly

the trunnion and side/drag brace

scissors (torque links)

actuating cylinder

down & up locks

the bungee system

Using hydraulics, landing gear retraction requires greater energy than lowering

Gear rotates on the trunnion pin

Extending landing gear requires a release of the UP lock first, then

The gear can begin free falling, slowed by the snubber in the orifice check valve

Final few degrees of travel may require hydraulic pressure assistance

Bungee system is used for emergency operation:

Gear doors must be operated before extension & after retraction

Landing Gear Position Indicator Systems

Positive indication must be provided to the pilot that gear is down & locked

Safety system includes squat switches and other microswitches

Squat switches tell pilot when weight of a/c is on the wheels

Squate switches are electrically “open” when on the ground

Some a/c use warning horns: they sound when:

If gear is retracted, and throttle retarded to below cruise

Landing gear position indicators: show position of Landing gear

May use a system of different color indicator lights

ku harap

someone touch my heart .........

Merenungi hari-hari sepi

Aku tanpamu

Masih tanpamu

Bila esok hari datang lagi

Ku coba untuk hadapi semua ini

Meski tanpamu meski tanpamu

Bila aku dapat bintang yang berpijar

Mentari yang tenang bersamaku disini

Ku dapat tertawa menangis merenung

Di tempat ini aku bertahan

Suara dengarkanlah aku

Apa kabarnya pujaan hatiku

Aku di sini menunggunya

Masih berharap di dalam hatinya

Suara dengarkanlah aku

Apakah aku slalu dihatinya

Aku di sini menunggunya

Masih berharap di dalam hatinya

Kalau ku masih tetap disini

Ku lewati semua yang terjadi

Aku menunggumu Aku menunggu

Suara dengarkanlah aku

Apa kabarnya pujaan hatiku

Aku di sini menunggunya

Masih berharap di dalam hatinya

Suara dengarkanlah aku

Apakah aku ada dihatinya

Aku di sini menunggunya

Masih berharap di dalam hatinya

hijau daun - suara ku berharap -

klik cni

http://www.youtube.com/watch?v=qk310y_oOxE

Luna Maya version here

http://www.youtube.com/watch?v=iLurjWrHKYQ

same like your voice ainan....

LANDING GEAR SYSTEMS

Landing Gear Configurations

Two main types: Conventional, and Tricycle

Has nose wheel, which may be steerable

Main gear, on either side

Example: Cessna

Keeps aircraft level during take-off and landing

The most important advantage is its ease of ground handling.

Two main wheels

One tail dragger wheel

Reduced drag in the air

Reduced landing gear weight

Requires more skill in ground taxiing

The most important advantage is the ability to operate the aircraft over rough terrain.

Classification of Landing Gear

Main landing gear

Cushions landing impact

Heavily stressed area

Main Landing Gear consists of the main weight-bearing structure

Auxiliary landing gear includes tail wheels, skids, nose wheels, etc.

Nonabsorbing Landing Gear

Includes Rigid landing gear, Shock-cord landing gear, Spring landing gear

Rigid: helicopters, sailplanes. No flexing other than the structure.

Shock cord system: uses “Bungee” cords

Spring type uses spring steel (some Cessna’s)

Shock-Absorbing Landing Gear

Dissipates landing energies by forcing fluid through a restriction

This fluid generates heat, dissipated into the atmosphere

Two types: Spring Oleo, and Air-Oil Oleo

Spring Oleo is history by now

Air Oleos are all very similar: a needle valve restricts fluid flow

Air in the oleo holds the weight of the a/c on the ground

Air Oleos present in both retractable and fixed gears

Fixed Gear

Non retractable, usually bolted on to the structure

Often uses fairings or wheel pants

Cessna 152

Advantages:

Lighter weight

Less compex

Least costly

Retractable Gear

Designed to eliminate drag (the greatest advantage)

Can be either fully or partially retractable

Direction of retraction depends on airframe model

Methods of retraction: hydraulic, electric, mechanical, pneumatic

Critical area of aircraft maintenance for safety reasons

Hulls and Floats

Can be single float, or multiple

Definition may include floating hulls (ex. “Lake” aircraft)

Floating hulls may only require wing tip floats

Skis used for snow and ice (wood, metal, composites)

Skis may use shock cord to assist angle of ski attack

Skis are mounted on the same strut as tires

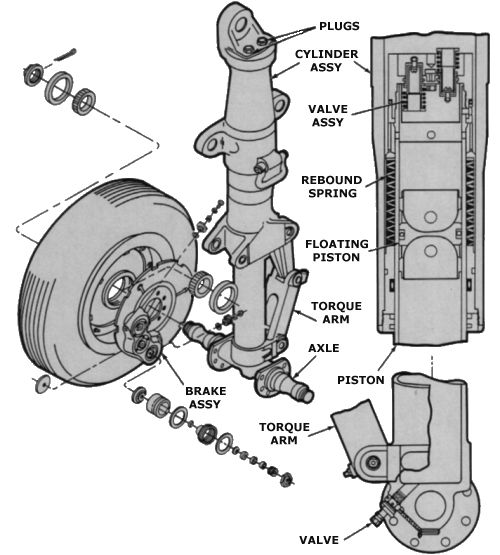

Landing Gear Components

Exact definitions of some components will vary

The Oleo strut is the widely used form of shock absorption on aircraft landing ge

ar.

Trunnions

Portion of the landing which attaches to the airframe

Supported at the ends by bearings

Landing gear traditionally extends from the center

Struts

Vertical member, contains the shock absorbing mechanism

Top of the strut mounts onto the trunnion

Strut forms the cylinder for the oleo (“outer” cylinder)

Piston is the moving portion (aka piston rod, tube or inner cylinder)

Oil is forced from the lower portion of the strut to the upper

Oil flow is restricted or varied according to a metering pin

Final weight of a/c rests on air in the top of the strut

Snubbers are used to prevent a sudden dropping of gear on takeoff

Metering pin controls the flow of fluid between the chambers.

The shock of landing is absorbed by the fluid being forced through a metered orifice. The metering pin gradually reduces the size of the orifice as the shock strut extends, which avoids a rapid extension after the initial shock of landing and related bounce.

Chevron seals are used in shock struts to prevent the oil from escaping

On nose wheel struts, a cam is built into the strut for the purpose of straightening

the nose wheel before retraction.

Filling a shock strut: “exercise” the strut in order to seat the seals, and remove air bubbles from the fluid.

Most shock strut oil levels are checked by releasing the air, bottoming the strut, and checking to see if the oil is at the level of the filler plug.

Information about shock struts: see:

Manufacturer’s maintenance manual

Information decal located on the strut

Mfr’s overhaul manual

Torque Links

Also called scissors assembly

Two A-frame members

Connects and aligns upper and lower cylinders

Connects the strut cylinder to the piston

Restricts extension of piston during retraction

Correctly aligns axle to the strut

Trucks

Located at the bottom of the strut piston

Axles are mounted on the truck

Trucks can tilt fore or aft to allow for a/c attitude changes

Drag Links

Stabilizes landing gear longitudiannly

May be hinged to allow retraction

Also called a drag strut

Side Brace Links

Stabilize gear laterally

May be hinged to allow retraction

Can be called a side strut

Overcenter Links (aka downlock mechanism)

Use to apply pressure to the center pivot joint in a drag or side brace link

Overcenter link is hydraulically retracted to allow gear retraction

Also called a downlock, and/or a jury strut

Swivel Glands

Flexible joint with internal passages

Route hydraulic fluid to the wheel brakes

Used where space limitation eliminate flex hoses

Shimmy Dampers

Hydraulic snubbing unit

Reduces tendency of nose wheels to oscillate

Piston type dampers

Piston and rod filled with hydraulic fluid

Piston has an orifice restricting speed of travel

Slow movement has no restriction

Large shimmy dampers incorporate temperature compensation

Vane type dampers

Employ stationary vanes and rotating vanes

Small passages restrict fluid movement

Central shaft rotation is restricted from moving quickly

Damper Inspections

Check for leakage & effectiveness of operation

Check mounting bolts and hardware

Most dampers are fairly reliable

Saturday, May 1, 2010

aircraft fuel systems

An aircraft fuel system allows the crew to store, manage, and deliver fuel to the propulsion system of an aircraft. Fuel systems differ greatly due to different performance of the aircraft in which they are installed. A single engine piston aircraft will have a very simple fuel system.

The fuel is piped through fuel lines to a Fuel Control valve (Fuel selector). This valve serves several functions. The first one is to act as a fuel shutoff valve. This is required to provide the crew with a mean to prevent fuel to be sent to the engine in case of an engine fire. The second role is to allow the pilot to choose which tank feeds the engine. Many aircraft have the Left Tank, Right Tanks selection available to the pilot. Some Cessnas have only the “Both tanks” feeding position, and many have the “Both tanks” position in addition to the Left and right. The reason to have the Left and Right Tank option is to allow pilots to balance fuel load

Fuel System

Most modern aircraft are equipped with 2 or more fuel tanks (or cells). In high wing aircraft, the cells are housed in the wings. Since they are higher than the engine, the fuel flows down to the engine by the force of gravity.

On low wing aircraft fuel pumps are required. To initially get fuel to the engine for starting, an electrical “boost pump” is turned on to pump fuel to the engine. After the engine is started, a mechanical fuel pump driven by the engine feeds fuel to the engine. The electric boost pump can now be turned off.

Each fuel tank is equipped with a drain valve located at the lowest point in the tank. This drain allows the pilot during preflight walk-around to check for and drain off any water which may have accumulated in the fuel tank. There is usually another drain located at the lowest part of the fuel piping system. This valve must also be drained during pre-flight to eliminate any water which may have accumulated in the fuel lines. Associated with this drain is a fuel strainer which filters out foreign matter which may be in the fuel system.

A vent line allows air to enter the tank as fuel is used. During hot weather, fuel may expand and overflow through the vent when tanks are full.

A fuel selector valve located inside the cockpit allows the pilot to select which tank(s) are to be in use during flight. Most small aircraft operate with the selector set on Both, such that both the left and right fuel tanks are simultaneous feeding fuel to the engine. The pilot may set the selector on Left or Right tank as a means of equalizing the loading of the aircraft. Usually, the selector should be set to both for take-off and landing. Pilots of low wing aircraft should exercise caution in their fuel management if tank selection is other than both. Running a tank dry can cause the engine to quit and vapour lock to occur in the fuel lines. It may be impossible to restart the engine under these conditions.

There is a fuel gauge in the cockpit for each fuel tank. The lower 1/4 of the fuel gauge indication is marked with a red line as a caution to the pilot of a low fuel condition. The pilot should never rely on the fuel gauge as the sole measure of fuel remaining. The gauges on aircraft are subject to a variety of indicator errors. The pilot should therefore double check the fuel remaining based on the power setting of the engine in flight and time in flight.

Inside the cockpit a fuel mixture control and a fuel primer pump are located on the instrument panel. The mixture control is used to adjust the air/fuel mixture for the altitude being flown. It allows the pilot to adjust the fuel/air ratio entering the engine. As altitude is gained, the intake air becomes less dense. Less fuel must be fed through the carburettor to permit the fuel/air mixture to remain correct proportion. If leaning is not accomplished by the pilot, a rich mixture (too much fuel) results. This is not only wasteful of fuel, but can result in fouled spark plugs due to carbon and soot buildup on the spark plugs. A rough running engine results. An additional gauge called an Exhaust Gas Temperature Gauge can be installed in the aircraft as an aid in achieving the proper “leaning” of the engine.

The fuel primer is a plunger that can be used in cold weather to inject fuel directly into the carburettor as an assist in starting the engine in cold conditions.

Three different grades of fuel are used in reciprocating engine aircraft. These grades are designated by octane rating and are colour coded so the pilot can insure the proper grade of fuel is being pumped into the tanks.

boeing 747 dream liner

nothing can fly without airfoil...

but i try my best to do it